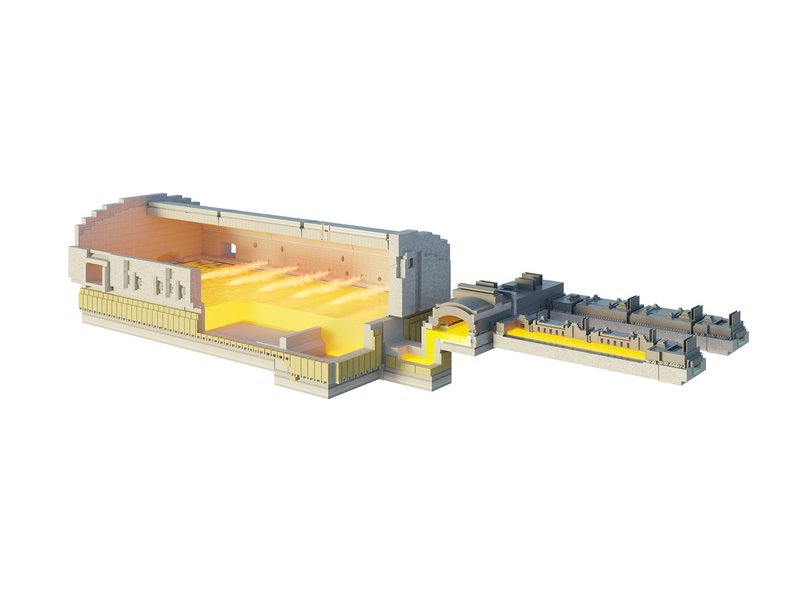

In high-temperature industries, energy waste is rarely dramatic—until it shows up on the fuel bill, the stack temperature report, or the maintenance log. Ceramic fiber modules manufactured by Zhengzhou Rongsheng Refractory Co., Ltd. are widely adopted in furnace and kiln linings because they combine low thermal conductivity, excellent thermal shock resistance, and fast installation. For procurement and technical managers, the point is simple: a properly designed module lining can reduce heat loss, shorten heat-up time, and stabilize production quality with fewer unplanned shutdowns.

Discussion prompt: Which problem is most urgent in your furnace—high shell temperature, long heat-up time, frequent lining cracks/spalling, or rising fuel consumption? Share your scenario and operating temperature range in the comments.

Most industrial furnaces lose energy through conduction (heat moving through the lining), radiation (hot surfaces radiating outward), and infiltration (air leakage and pressure imbalance). Even “acceptable” losses become expensive when a furnace runs continuously. According to commonly cited industrial energy assessments, 10–20% of fuel input in aging high-temperature equipment can be wasted due to insulation deterioration, structural gaps, and excessive shell temperature. In severe cases, losses can be higher—especially in cyclic heating processes where thermal shock accelerates lining damage.

Ceramic fiber modules are engineered insulation units made from high-temperature ceramic fibers, typically pre-compressed and assembled to form a resilient lining system. Their energy-saving effect is not a marketing slogan—it comes from a few measurable physical realities.

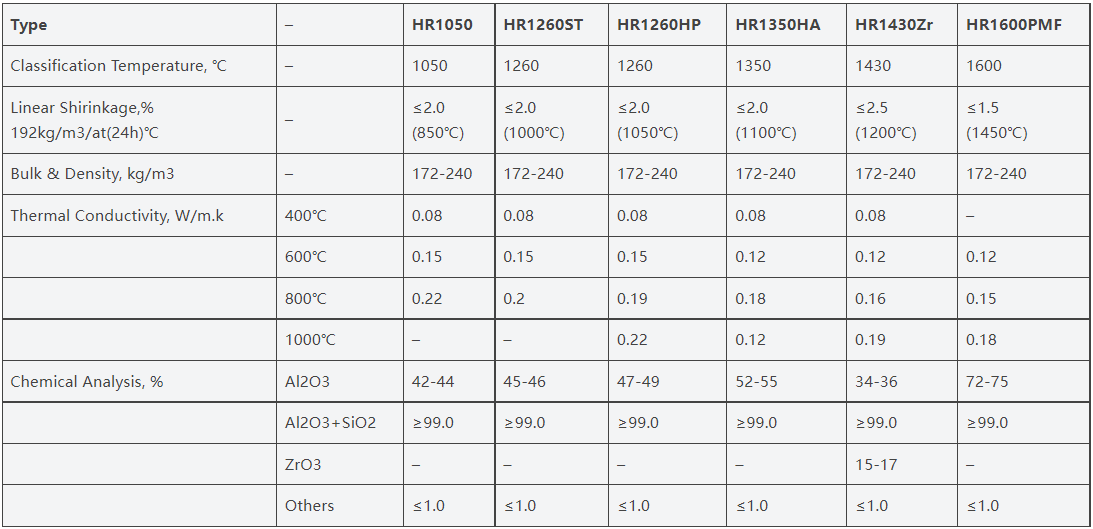

In general, ceramic fiber insulation exhibits significantly lower thermal conductivity than dense refractories, especially in the mid-to-high temperature range. For reference, typical ceramic fiber insulation products may show thermal conductivity around 0.12–0.20 W/m·K at approximately 600°C (exact values vary by grade and density). Lower conductivity means less heat flows outward through the wall—directly reducing fuel demand to maintain setpoint.

Another hidden cost in kilns and furnaces is the energy used to heat the lining itself. Ceramic fiber modules have low heat capacity and low density, so they store less heat than traditional refractory brick systems. For plants running batch cycles or frequent temperature swings, reduced thermal mass often translates into faster heat-up and less energy lost during cooldown. In many retrofit projects, end users report 5–15% fuel savings depending on the baseline lining condition, operating temperature, and leak management.

Spalling and cracking are not just maintenance problems—they are efficiency problems. When a lining breaks down, gaps form, anchors loosen, and hot spots appear, increasing heat loss and safety risk. Ceramic fiber modules are inherently more tolerant of rapid temperature changes than many rigid refractory systems. In real industrial operations, this is valuable in start-stop production, emergency shutdowns, and uneven thermal loading near burners, doors, and flue transitions.

Purchasing decisions in refractory insulation rarely come down to a single parameter. Technical teams typically evaluate heat containment, reliability, installation time, and long-term maintenance behavior. The comparison below reflects how many industrial sites frame the trade-offs during an energy-saving retrofit.

Ceramic fiber modules are not limited to one niche. They are often specified in furnaces and kilns where high temperature stability and continuous insulation integrity matter. Below are representative scenarios where engineering teams commonly choose modules in energy-saving retrofits or new builds.

In heat-treatment furnaces, reheating furnaces, and ladle-related thermal equipment, maintaining uniform temperature can directly affect metallurgical properties and yield. Plants often target lower shell temperature and fewer hot spots. In multiple retrofit projects reported across the industry, module linings have helped reduce external surface temperature by 30–80°C in localized hot areas after sealing and insulation optimization (site-dependent), while improving temperature stability during long holds.

Fired heaters and process furnaces face harsh conditions: vibration, pressure fluctuations, and demanding uptime. Module systems are often valued for rapid turnaround installation and reduced lining damage during thermal cycling. In outage planning, every saved hour matters—faster installation can meaningfully reduce downtime exposure when paired with proper anchoring design and inspection routines.

For ceramic kilns, energy cost is a persistent pressure point. Lining upgrades typically aim to lower heat loss while keeping kiln atmosphere and temperature uniform. Modular fiber solutions can support faster cycle times and consistent firing results, especially when kiln schedules involve frequent ramping and cooling.

If you were to change only one thing in your current lining design, would it be insulation thickness, anchor layout, door/penetration sealing, or hot-face material selection? The answer often reveals where the real energy loss is happening.

In many industrial plants, the best insulation plan is the one that can actually be executed within the turnaround schedule. Ceramic fiber modules are designed for efficient on-site assembly, helping teams reduce labor intensity and compress installation time. When aligned with a well-defined lining plan—including corner treatment, expansion allowances, and penetration detailing—modules can also reduce common failure points such as gaps and shrinkage-related leaks.

In refractory and insulation procurement, “spec compliance” is not paperwork—it is risk control. Reliable ceramic fiber module supply typically includes documented quality systems and material traceability. Many industrial buyers look for manufacturing controls aligned with ISO 9001 quality management and request supporting documentation such as material test reports, density and shrinkage data, and relevant compliance statements depending on the destination market and application environment.

For international projects, consistent documentation can reduce approval time during EPC coordination, help standardize site acceptance criteria, and support smoother commissioning—especially when the furnace is part of a regulated process line.

With correct grade selection and lining design, modules can perform reliably in sustained heat. The key is matching the fiber classification temperature to your operating setpoint and considering atmosphere and velocity effects near burners and flues.

Savings typically come from lower wall heat flux, reduced shell temperature, and faster ramp-up due to lower thermal mass. In many retrofit scenarios, plants target 5–15% fuel reduction; higher results may be achievable when the baseline lining is degraded or leakage is corrected alongside insulation.

It is typically faster, but still requires disciplined execution: anchor arrangement, module orientation, joint compression, and sealing around penetrations. A well-prepared drawing package and on-site supervision are what convert speed into long-term reliability.

Get a technical recommendation for ceramic fiber modules for industrial kiln energy-saving retrofits—including grade selection, lining thickness guidance, and application notes based on your operating temperature and furnace type.

Request Ceramic Fiber Module Technical ConsultationTip for faster support: include furnace drawings, operating temperature, fuel type, and the last maintenance record of hot spots.

Keywords: ceramic fiber modules, industrial furnace energy saving, kiln insulation, refractory materials, low thermal conductivity insulation, thermal shock resistant lining, furnace retrofit insulation.