Ceramic Fiber Modules for Industrial Kiln Energy Saving: Lower Heat Loss, Higher Thermal Efficiency

2026-02-17

Technical knowledge

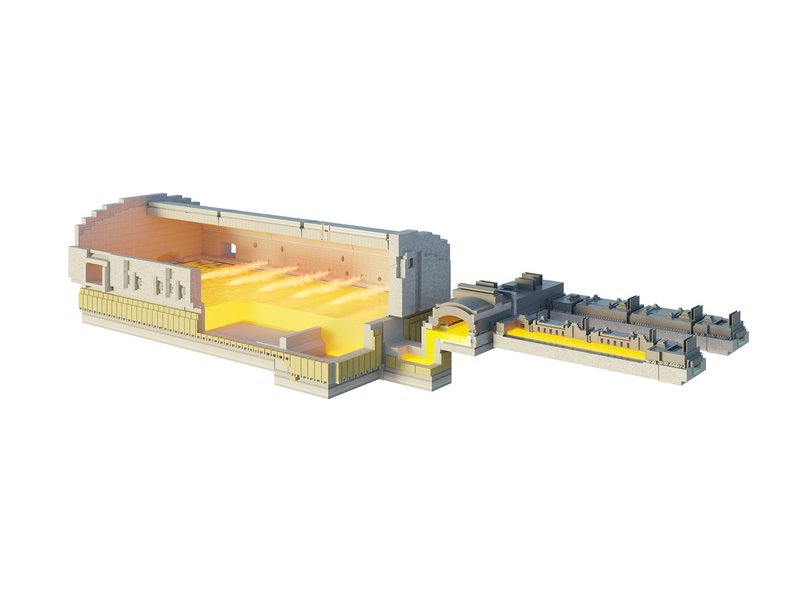

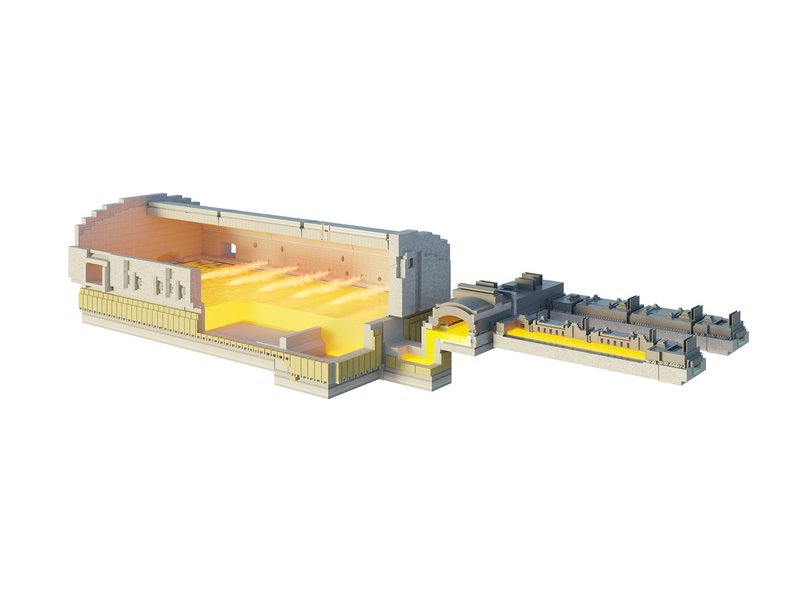

Industrial kilns and furnaces face persistent energy-efficiency challenges driven by high shell temperatures, continuous radiant loss, and insulation aging under thermal cycling. Ceramic fiber modules are presented as a high-efficiency energy-saving option, leveraging low thermal conductivity insulation to reduce heat loss, stabilize hot-face temperatures, and improve overall thermal efficiency. Designed for high-temperature lining systems, these modules typically operate reliably across 1050°C–1400°C (grade dependent) and maintain performance under severe thermal shock, supporting stable production in steel, petrochemical, and ceramics applications. Compared with traditional dense refractories, ceramic fiber modules can deliver thinner linings with strong insulation performance, lower heat storage, and faster heat-up/cool-down response—translating into reduced fuel consumption and improved process control. Their modular, anchored installation method also shortens shutdown time, simplifies construction, and reduces labor intensity, making retrofit projects more practical for energy-upgrade schedules. Supported by internationally recognized quality and compliance certification, ceramic fiber modules help manufacturers pursue green, low-carbon upgrading while maintaining high-temperature safety margins and long-term operational reliability.

Industrial Furnace Energy Retrofit: How Ceramic Fiber Modules Cut Heat Loss and Raise Efficiency

Across steel, petrochemical, and ceramic production, industrial furnaces and kilns still account for a large share of plant energy consumption. In many sites, the bottleneck is not the burner or the control system—it is the lining. When heat escapes through walls and roof, fuel demand rises, warm-up takes longer, and surface temperatures increase safety risk. Ceramic fiber modules are increasingly positioned as a high-efficiency energy-saving choice because they reduce thermal losses while keeping installation and maintenance practical for real-world shutdown windows.

Industry pain point (common on-site observation): “We upgraded burners and tuning, but the furnace still consumes more gas than expected. The shell stays too hot, and temperature uniformity is hard to hold during cyclic production.”

Why Furnace Lining Matters More Than Many People Expect

In continuous or batch furnaces, lining performance impacts three measurable indicators: heat storage (how much energy the lining “soaks up” each cycle), heat transfer (how fast heat leaks out), and air infiltration resistance (how well the lining maintains integrity through thermal cycling). Traditional dense refractories can be durable, but they often bring higher thermal mass and higher conductive losses than modern fiber linings, especially during frequent start-stop operations.

Ceramic fiber modules are engineered as pre-compressed blocks (often folded or layered) that expand to form tight, resilient insulation. For plants targeting carbon reduction and fuel cost control, this insulation approach is frequently one of the fastest ways to unlock “invisible” efficiency gains without redesigning the entire furnace.

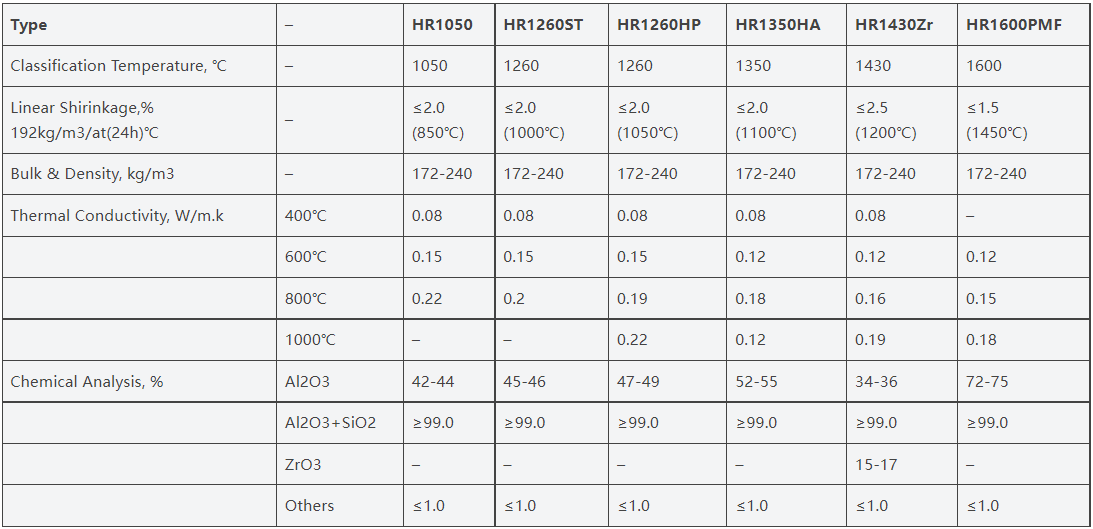

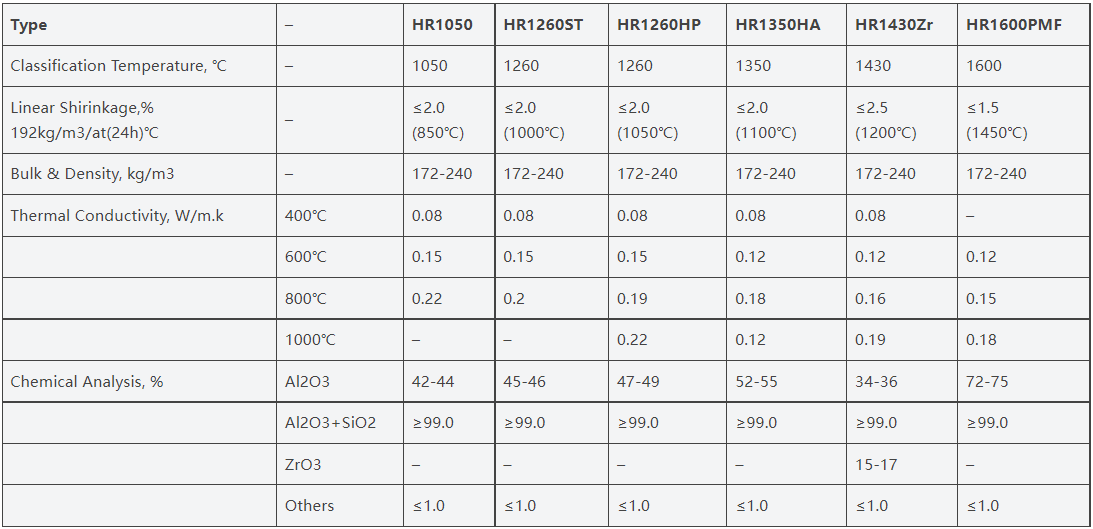

Core Performance Data: What Ceramic Fiber Modules Typically Deliver

1) Service temperature range for high-temperature linings

Common industrial-grade ceramic fiber modules cover a broad spectrum of furnace needs. Typical continuous service temperatures range from 1050°C to 1400°C (depending on fiber chemistry and classification). This makes them suitable for many reheating furnaces, heat treatment lines, reformers, cracking furnaces, and ceramic kilns where thermal stability and predictable insulation are required.

2) Low thermal conductivity = less heat leakage

The main reason modules cut energy loss is their low thermal conductivity compared with many conventional linings. As a reference, quality ceramic fiber insulation often measures around:

| Mean Temperature |

Typical Thermal Conductivity (Ceramic Fiber Module) |

Practical Interpretation |

| 400°C |

≈ 0.11 W/m·K |

Good baseline insulation for mid-zone and back-up lining |

| 800°C |

≈ 0.20 W/m·K |

Lower conduction helps stabilize hot-face temperatures |

| 1000°C |

≈ 0.28 W/m·K |

Meaningful reduction of shell losses in many industrial furnaces |

In real retrofits, plants often report measurable outcomes such as 5%–15% fuel savings (process-dependent), reduced external surface temperature, and improved temperature uniformity—especially where thermal cycling previously punished dense linings. Actual results depend on lining thickness, furnace geometry, operating temperature, leakage, and burner tuning.

3) Low heat storage for faster heat-up and tighter cycles

A key difference between fiber modules and many traditional refractories is thermal mass. Fiber linings store less heat, which commonly translates into shorter start-up time and less “wasted” energy during cooldown. For batch operations, this can be as valuable as pure insulation, because every cycle becomes more efficient and repeatable.

4) Thermal shock resistance in cycling furnaces

Ceramic fiber modules are inherently resilient against rapid temperature changes. In production realities—door openings, charging/discharging, emergency stops—this resistance reduces cracking and spalling risk, helping keep the lining tight and insulation performance stable over time.

Module vs. Traditional Refractory: Practical Advantages That Show Up on the Plant Floor

Better insulation for the same space

Where furnace dimensions limit lining thickness, ceramic fiber modules can provide higher insulation efficiency per unit thickness than many dense materials. This can be decisive in revamps where increasing wall thickness is not feasible.

Shorter installation time and predictable shutdown planning

Modules are typically anchored and fitted with standardized geometry, reducing the need for long curing/drying schedules associated with some castables. In many retrofits, this can help shorten turnaround time by 20%–40% and reduce labor intensity—one reason they are promoted as a high-efficiency energy-saving choice for maintenance teams.

Lower shell temperature, improved safety margin

Better insulation performance commonly results in a cooler casing. Many plants use shell temperature mapping as a routine KPI; after fiber module upgrades, it is not unusual to see shell temperatures drop by 30°C–80°C in hotspots (site conditions vary). Lower shell temperature supports operator safety and can reduce heat load in surrounding workshops.

Where Ceramic Fiber Modules Perform Best: Typical Industry Applications

Steel & Metallurgy: reheating, heat treatment, and soaking zones

In steel operations, the focus is often on reducing fuel per ton and improving temperature uniformity. Fiber modules can help reduce wall losses and stabilize hot-face conditions, supporting tighter process control. They are also valued for thermal cycling resilience in equipment that sees frequent door operations or irregular production rhythms.

Petrochemical: reformers, cracking furnaces, and hot-gas equipment

Petrochemical furnaces push high temperatures and demand reliable insulation to avoid unnecessary heat leakage and casing overheating. Ceramic fiber modules, when properly selected for the temperature class, offer stable insulation from 1050°C up to 1400°C and can support maintenance strategies focused on uptime. For many operators, the value is not only fuel savings, but also more predictable thermal behavior in critical areas.

Ceramics: shuttle kilns, tunnel kilns, and batch kilns with frequent cycles

Ceramic production often involves repeated heating and cooling where thermal shock resistance matters. Fiber modules’ low heat storage can reduce cycle energy waste, while consistent insulation performance supports uniform firing. For plants pursuing decarbonization targets, this is a practical lever to help enterprises upgrade toward green and low-carbon operations without disrupting core product recipes.

Quality Assurance and International Compliance: What Buyers Typically Check

For B2B buyers, “energy-saving” claims need to survive audits, safety reviews, and long-term procurement logic. High-quality ceramic fiber modules are commonly supplied under structured quality systems (for example, ISO 9001), and many suppliers can provide material traceability, dimensional tolerance control, and standardized test reports for thermal conductivity, density, and linear shrinkage.

In project specifications, buyers often request documentation that supports internal compliance processes—especially in regulated industries. Clear certifications and stable batch performance reduce procurement risk and help engineering teams justify the retrofit with measurable parameters rather than marketing language.

A Practical Retrofit Checklist (Engineering-Oriented)

- Operating temperature profile: confirm hot-face temperature and peak events; select 1050°C–1400°C class accordingly.

- Target shell temperature: set a measurable KPI for safety and energy loss reduction (before/after mapping).

- Module thickness & density: balance insulation level, mechanical integrity, and available space.

- Anchoring method: verify alloy selection and layout for thermal cycling and vibration conditions.

- Maintenance access: plan for inspection points, doors, joints, and high-wear areas.

- Expected ROI drivers: quantify fuel savings, reduced downtime, and labor savings from faster installation.

CTA: Upgrade Your Furnace Lining for Real Efficiency Gains

Looking for a ceramic fiber module solution that supports high-temperature stability, faster installation, and measurable heat-loss reduction? Get a technical recommendation based on your operating temperature, lining thickness limits, and shutdown schedule—built for practical field execution and helping enterprises upgrade toward green operations.

Request a Ceramic Fiber Module Lining Proposal

Suggested inputs: furnace type, max operating temperature, lining thickness, hot-face area size, current shell temperature, and production cycle.

Question for engineers and maintenance teams

In your current furnace or kiln operation, what is the biggest source of energy waste—shell heat loss, long warm-up time, temperature non-uniformity, or frequent lining repairs?

.png?x-oss-process=image/resize,h_100,m_lfit/format,webp)

.png?x-oss-process=image/resize,h_100,m_lfit/format,webp)

.png?x-oss-process=image/resize,h_100,m_lfit/format,webp)

English

English