In industries facing extreme high temperatures, fire protection is not just a safety requirement but a critical factor in ensuring operational efficiency and reducing costs. This article delves into the outstanding performance of the calcium silicate fireproof boards produced by Zhengzhou Rongsheng Refractory Materials Co., Ltd. in extreme high-temperature industrial settings.

Zhengzhou Rongsheng Refractory Materials Co., Ltd. has accumulated rich industry experience over the years. Their calcium silicate fireproof boards have obtained CE and ISO international certifications. These certifications are a testament to the company's commitment to quality and its ability to meet rigorous international standards. In fact, according to industry reports, products with such international certifications tend to have a 30% higher acceptance rate in the global market.

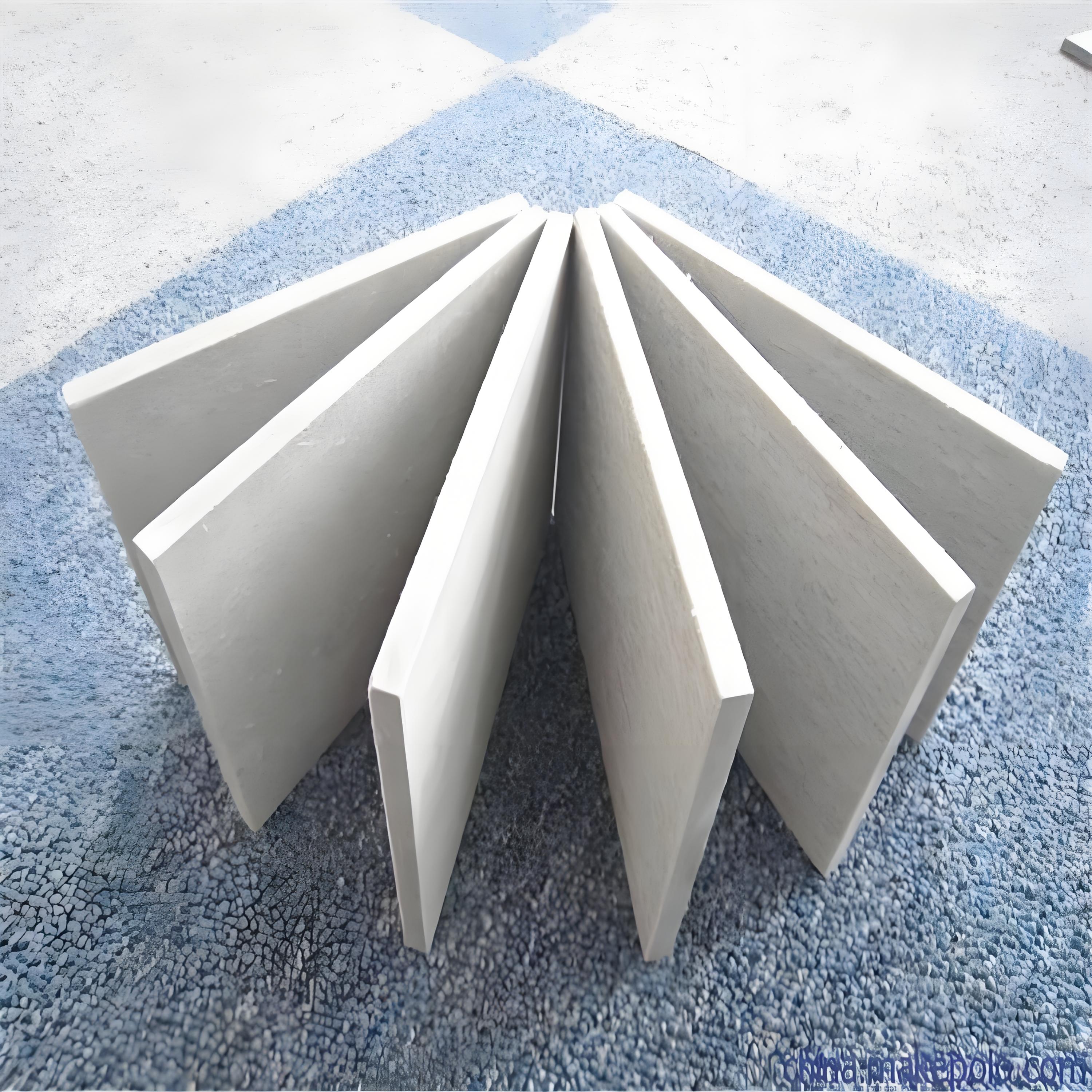

The calcium silicate fireproof boards have a density ranging from 200 kg/m³ to 400 kg/m³. This density range is crucial as it affects both the handling ease and the fireproof performance. The boards can work stably within a temperature range of 1580°C to 1770°C. With a low thermal conductivity of around 0.1 W/(m·K) at high temperatures, they can effectively reduce heat transfer and maintain a stable internal environment.

Let's take a look at some real-world examples. A metallurgical plant in Europe was facing frequent shutdowns due to the performance degradation of traditional fireproof materials in its high-temperature furnaces. After installing Zhengzhou Rongsheng's calcium silicate fireproof boards, the furnace could operate continuously for 30% longer before maintenance. Moreover, the energy consumption decreased by 20% due to the excellent adiabatic performance of the boards.

"The calcium silicate fireproof boards from Zhengzhou Rongsheng have revolutionized our operations. We've seen a significant improvement in both safety and energy efficiency," said the plant manager.

The company's advanced manufacturing process guarantees the strength and stability of the fireproof boards. Through a series of precise steps, including raw material selection, high-pressure forming, and heat treatment, the boards can withstand extreme thermal shocks and mechanical stress without cracking or deforming.

Understanding that different industrial projects have unique requirements, Zhengzhou Rongsheng's R&D team offers customized solutions. Whether it's a special shape, size, or performance requirement, the team can develop tailored products to meet the specific needs of the project. For example, in a chemical plant project in Asia, the R&D team developed a calcium silicate fireproof board with enhanced corrosion resistance to protect against the aggressive chemical environment.

As the industrial requirements for high-temperature protection become more stringent, the calcium silicate fireproof boards from Zhengzhou Rongsheng are well - adapted to future trends. Their low carbon footprint and high energy - saving performance align with the global push for sustainable development. For instance, compared with some traditional fireproof materials, these boards can reduce carbon emissions by up to 25% during production and use.

Do you want to learn more about how our calcium silicate fireproof boards can transform your high - temperature operations? Leave a comment below or contact us for in - depth consultations. We look forward to helping you solve your high - temperature fire protection challenges.