In today's competitive industrial landscape, energy efficiency has become more than just an environmental consideration—it's a critical factor in operational profitability. According to the International Energy Agency (IEA), industrial furnaces and kilns account for approximately 7% of global energy consumption, with heat loss through refractories representing one of the largest inefficiencies. For manufacturing facilities operating high-temperature processes, reducing this heat loss can translate to significant cost savings and improved environmental performance.

Traditional refractory materials often allow heat loss rates of 20-30% in standard industrial kiln operations. This not only increases energy consumption but also leads to uneven temperature distribution, longer heating cycles, and increased wear on equipment components. For a medium-sized ceramic production facility operating 24/7, this can result in annual energy costs exceeding $150,000—costs that could be significantly reduced with improved insulation technology.

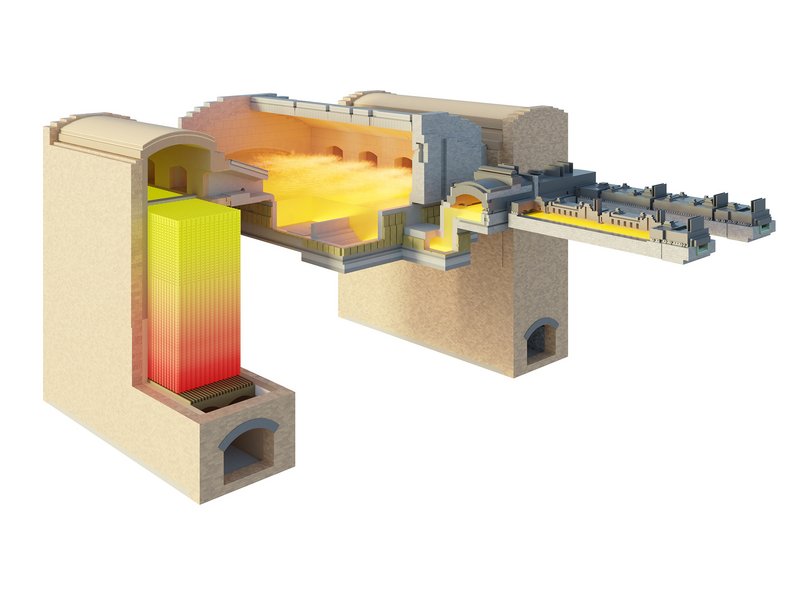

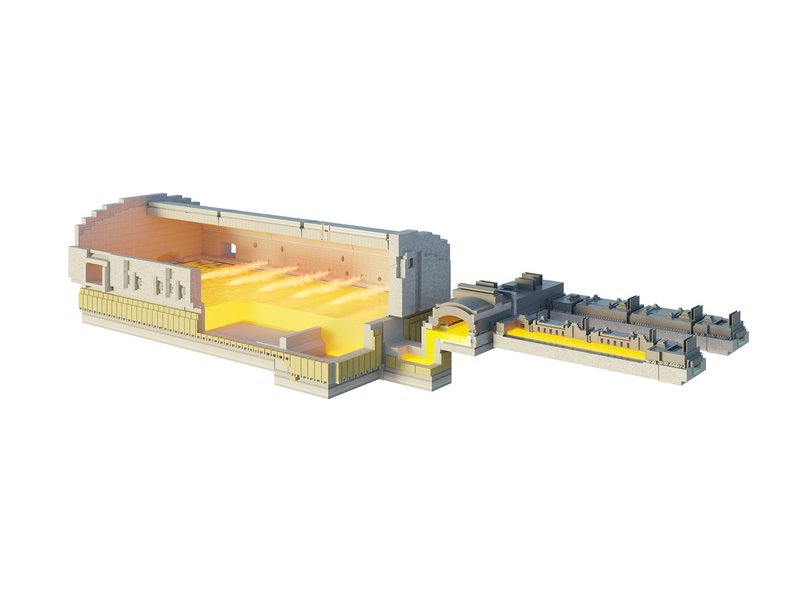

Zhengzhou Rongsheng Refractory Material Co., Ltd. has developed advanced ceramic fiber modules that address these inefficiencies through superior material science. These modules combine low thermal conductivity (as low as 0.12 W/m·K at 1000°C) with exceptional thermal shock resistance, creating a high-performance insulation solution that can withstand operating temperatures from 650°C up to 1600°C depending on the specific formulation.

The performance benefits of these ceramic fiber modules are not just theoretical—they've been proven in real industrial settings across multiple sectors:

A major steel manufacturer in Hebei province upgraded their 12-meter reheating furnace with Rongsheng ceramic fiber modules. The results were impressive:

In the ceramic industry, a tile manufacturer in Guangdong replaced traditional firebricks with ceramic fiber modules in their tunnel kiln. This upgrade resulted in a 16.3% reduction in coal consumption and allowed for faster firing cycles, increasing daily production by 12% while maintaining product quality standards.

Beyond thermal performance, Rongsheng's ceramic fiber modules offer significant installation benefits. The pre-engineered modular design allows for straightforward installation with minimal specialized labor. Each module is designed to interlock securely, creating a seamless insulation layer with minimal joints—critical for reducing heat loss points.

All Rongsheng ceramic fiber modules meet international quality standards, including ISO 9001 certification, and are tested to withstand the rigorous conditions of industrial furnace environments. The materials are non-toxic, asbestos-free, and comply with CE safety requirements, ensuring safe handling and operation.

As global industries face increasing pressure to reduce carbon footprints and meet sustainability targets, energy-efficient solutions like ceramic fiber modules play a crucial role. By reducing energy consumption, these modules not only lower operational costs but also decrease greenhouse gas emissions. For companies looking to demonstrate environmental responsibility while improving their bottom line, investing in high-performance insulation represents a win-win solution.

Have you experienced challenges with heat loss in your industrial kiln operations? What energy-saving measures have you implemented, and what results did you achieve? Share your experiences in the comments section below—we'd love to hear from industry professionals facing similar challenges.

Discover how Rongsheng ceramic fiber modules can transform your industrial furnace efficiency and bottom line.

Get Your Custom Energy-Saving Proposal Today