In the realm of high-temperature industrial operations, where equipment reliability and energy efficiency are critical, the selection of thermal insulation materials directly impacts operational costs and process stability. Zhengzhou Rongsheng Refractory Materials Co., Ltd. has established itself as a trusted provider of polycrystalline mullite fiber boards, offering tailored thickness solutions that precisely match diverse industrial工况 requirements.

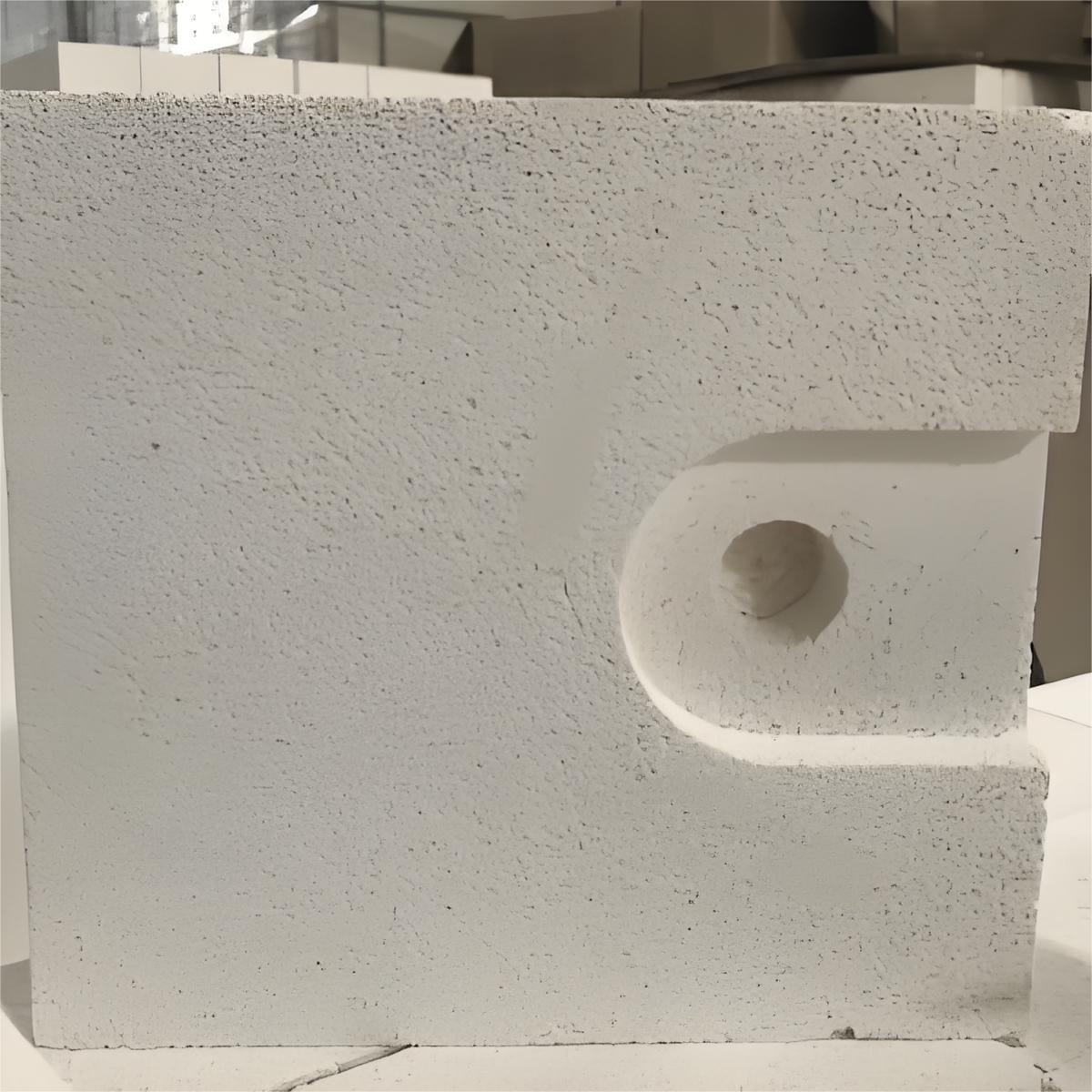

"The optimal thickness of thermal insulation materials represents a critical balance between energy efficiency, equipment weight, and operational safety. Our 3-100mm customizable polycrystalline mullite fiber boards provide engineering teams with precise control over this balance," explains Dr. Wei Zhang, Chief Materials Engineer at Zhengzhou Rongsheng.

Polycrystalline mullite fiber boards offer exceptional thermal stability up to 1600°C, making them ideal for extreme temperature environments. The ability to customize thickness from 3mm to 100mm allows for precise engineering solutions across various industrial applications:

Zhengzhou Rongsheng maintains rigorous quality control standards, holding both ISO9001 certification and CE marking. This dual certification framework ensures:

Consistent production quality with less than 0.5% defect rate across all product lines

Conformance with European safety, health, and environmental protection requirements

These certifications have positioned Zhengzhou Rongsheng as a preferred supplier in over 40 countries, with particularly strong market presence in Germany, Saudi Arabia, and the United States.

Beyond product supply, Zhengzhou Rongsheng offers comprehensive technical support, including on-site installation guidance and thermal performance analysis. Their team of 12 field engineers provides responsive service with average on-site response times of 48 hours for major industrial regions.

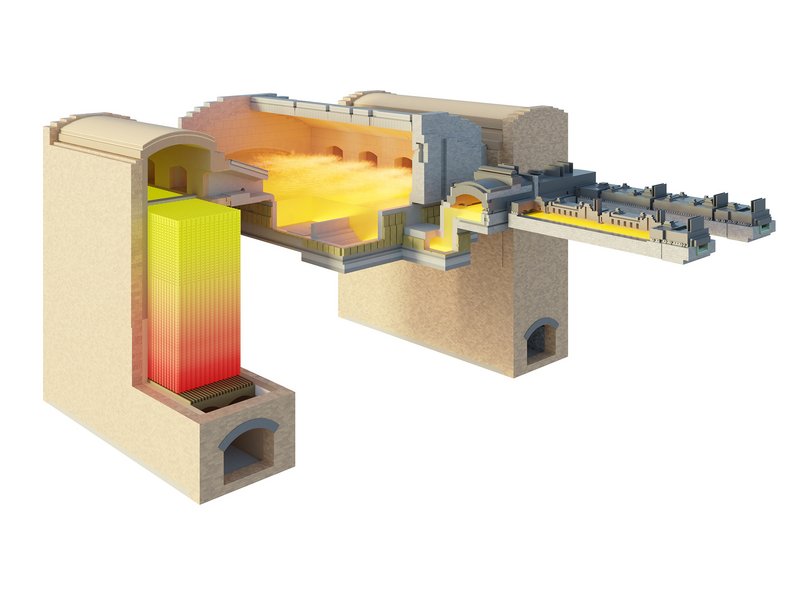

Case studies across various high-temperature industries demonstrate the tangible benefits of properly specified polycrystalline mullite fiber boards:

A major steel manufacturer in Hebei Province implemented 80mm polycrystalline mullite fiber boards in their continuous casting tundishes, resulting in:

In the petrochemical sector, a refinery in Texas upgraded their catalytic reformer units with 50mm customized boards, achieving stable operating temperatures with 15% lower fuel consumption and reducing maintenance downtime by 22% annually.

Ceramic manufacturers have similarly benefited, with one tile producer in Italy reporting 28% faster firing cycles and 12% energy savings after implementing 30mm polycrystalline mullite fiber boards in their tunnel kilns.

When determining the appropriate thickness for your specific application, consider these key factors:

Get personalized thickness recommendations for your industrial equipment from our technical experts

Request Custom Thickness AnalysisWith over 15 years of experience in high-temperature insulation solutions, Zhengzhou Rongsheng combines material science expertise with practical engineering knowledge to deliver optimal insulation solutions. Their polycrystalline mullite fiber boards have been tested and validated in some of the world's most demanding industrial environments, consistently delivering measurable improvements in energy efficiency and operational reliability.

For technical specifications, material samples, or to discuss your specific application requirements, contact their international sales team via the link above. Engineering support is available in English, German, Spanish, and Mandarin to ensure clear communication throughout your project lifecycle.